Watch Prototype

Introduction

Given 3 products to choose from a shoe, a watch or a camera.

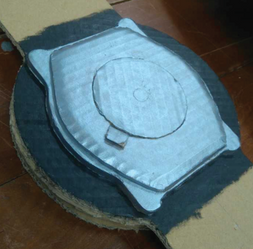

My group picked the product, watch, to make a prototype in the scale of 1 to 5. Using cardboards instead of blue foam, my team and I created the first giant coloured working prototype watch.

Prototype

My contributions

I was in charged of the face and back of the watch. The details of it is not as easy as I initially thought it would be. I had to ensure that each piece was precise.

It was challenging as I could not see the line separating the numbers and the face of the watch (printed on the paper). Thus, estimating how far I should cut it, I traced the outline of the cutouts (numbers) on the cardboard and cut it out with a penknife. The size of the penknife was wider then a regular penknife which makes it difficult to cut out accurately. I switch to a regular penknife and held it similar to how I would hold a pen, to have better control and accuracy when cutting out.

Learning Points

During the prototyping process, I realized that I cannot rush such a delicate process. Any haste could result in a mess up and the need to redo. This project taught me to be patient when doing tiny details. The tools we used also play a part as well. Rushing through the process will also only increase the time needed to complete.